Hydrogels are versatile biomaterials that have gained a significant amount of interest from various industries. A hydrogel is a three-dimensional structure made of natural or synthetic polymers. This three-dimensional polymer network is capable of retaining significant amounts of water or biological fluids. Hydrogels have a water content ranging between 20 and 99+ percent. They are widely used for different purposes, most of which benefit from the added property of hydrophilicity of the gel. Hydrogels can be considered as a foundational platform for new inventions in many fields. This is due to their excellent properties, which make them suitable for a very wide range of applications. They are characterized by their ability to swell and absorption of moisture while remaining intact. This quality is the cornerstone of their function in a variety of products such as hydrogel dressings and agricultural aids.1,2

In this article, we look at what hydrogels are, their structure, chemistry and properties, and their many applications. This guide is intended to serve as a comprehensive guide for anyone interested in this extraordinary substance.

The Structure of Hydrogels

The structure of hydrogels is characterized primarily by their continuous network structure. This is an important feature of stabilized hydrogels. The formation of this network structure is achieved through physical or chemical cross-linking of polymeric chains. Such cross-linking can be obtained through various mechanisms, such as covalent bonding, hydrogen bonding, or ionic interactions.

The mechanical properties of these materials are significantly affected by the three-dimensional arrangement of the hydrogels’ networks as well as the density of the crosslinks.3

Structure Created by Cross-Linking

A cross-linked polymer network is the basic structure of a hydrogel. This structure delivers mechanical strength and stability to the hydrogel.

Cross-linking is the process that joins polymer chains and develops a three-dimensional network within the material. It can be achieved by either physical or chemical linking:

- Physical Cross-linking: This involves weak interactions like hydrogen bonding or ionic bonds. Hydrogels with physical cross-links are often reversible and can dissolve under certain conditions.

- Chemical Cross-linking: This involves covalent bonds, which are stronger and more stable vs physically cross-linked bonds. Hydrogels with chemical cross-links are generally irreversible.

Chemistry of Hydrogels

Hydrogels can be derived from various sources, including both natural and synthetic polymers.4 These are listed below.

Common Natural Polymers Used for Hydrogel

- Polysaccharides:

- Cellulose

- Chitosan

- Alginate

- Hyaluronic acid

- Proteins:

- Collagen

- Gelatin

Common Synthetic Polymers Used for Hydrogel

- Poly(ethylene glycol) (PEG)

- Poly(vinyl alcohol) (PVA)

- Poly(acrylamide) (PAAm)

Key Properties of Hydrogels

The characteristics of a hydrogel can vary greatly and depend largely on the material’s internal structure and chemistry.

Below are some of the properties of hydrogel.

- High Water Content: Hydrogels can absorb and retain large amounts of water, often exceeding their dry weight.

- Biocompatibility: Many hydrogels are biocompatible, making them suitable for biomedical applications.

- Mechanical Properties: The mechanical properties of hydrogels can be tuned by adjusting the cross-linking density and polymer chain length. Mechanical properties can range widely, from soft and flexible to extremely tough and stretchable.

- Stimuli-Responsiveness: Changes in temperature, pH, or electric fields may cause corresponding changes in the volume, shape, and appearance of the hydrogel

- Self-Healing: Self-healing hydrogels can be engineered. This specific property would be quite beneficial when it comes to durability and extending lifespan

Properties Are Largely Determined by Chemistry and Cross-Linking Mode

The features of a polymeric hydrogel are largely determined by the polymer type and the mode of cross-linking. At a result, the properties of a hydrogel can be fine-tuned using these as levers. For instance, chemistry and cross-linking adjustments could be used to alter things like swelling capacity, mechanical strength, and biocompatibility.

Types of Hydrogels

Hydrogels can be classified based on several factors, including their origin, cross-linking method, and properties.4,5 Here are some of the main types of hydrogel:

Types Based on Origin

Below is an overview of different types of hydrogel based on origin.

- Natural Hydrogels:

- Natural hydrogels are prepared from polymers that are derived from natural sources, such as plants, animals, or microorganisms. Examples of natural polymers are alginate, chitosan, gelatin, cellulose, etc.

- Properties: Hydrogels prepared from natural polymers offer biocompatibility, biodegradability, and low toxicity.

- Limitations: They have limited mechanical strength and are susceptible to microbial degradation.

- Natural hydrogels are prepared from polymers that are derived from natural sources, such as plants, animals, or microorganisms. Examples of natural polymers are alginate, chitosan, gelatin, cellulose, etc.

- Synthetic Hydrogels:

- Synthetic hydrogels are prepared from synthetic polymers, such as polyvinyl alcohol, polyacrylamide, polyethylene glycol, etc.

- Properties: Synthetic hydrogels offer tunable properties, high mechanical strength, and stability.

- Limitations: They have low biodegradability and have the potential to cause toxicity.

- Synthetic hydrogels are prepared from synthetic polymers, such as polyvinyl alcohol, polyacrylamide, polyethylene glycol, etc.

- Hybrid or Semi-Synthetic Hydrogels:

- Hybrid hydrogels are prepared by combining natural and synthetic polymers. Such hydrogels offer improved properties like biocompatibility, mechanical strength, and degradability.

Types Classified by Cross-Linking

The material can also be classified based on the the type of cross-linking used to create it. We break down the different types in more detail below:

- Physical Hydrogels:

- Physical hydrogels are cross-linked by weak forces like hydrogen bonding, ionic interactions, or hydrophobic interactions.

- Properties: They are reversible and are biocompatible.

- Limitations: They have lower mechanical strength and stability.

- Physical hydrogels are cross-linked by weak forces like hydrogen bonding, ionic interactions, or hydrophobic interactions.

- Chemical Hydrogels:

- Chemical hydrogels are cross-linked by covalent bonds.

- Properties: They offer high mechanical strength and stability.

- Limitations: They have the potential for toxicity and are difficult to degrade.

- Chemical hydrogels are cross-linked by covalent bonds.

Types Categorized by Properties

You can also classify hydrogel types based on their properties, such as ones that are conductive or stimuli-responsive. We provide an overview of some of these below:

- Stimuli-Responsive Hydrogels:

- These are smart hydrogels that have the ability to respond to external stimuli like pH, temperature, light, or ionic strength.

- Uses: Stimuli-responsive hydrogels have been widely used in drug delivery, tissue engineering, and biosensors.

- These are smart hydrogels that have the ability to respond to external stimuli like pH, temperature, light, or ionic strength.

- Super Absorbent Hydrogels:

- Superabsorbent hydrogels can absorb very large amounts of water, often many times their weight.

- Uses: They are widely used in diapers, sanitary napkins, and agriculture.

- Superabsorbent hydrogels can absorb very large amounts of water, often many times their weight.

- Conductive Hydrogels:

- Conductive hydrogels are capable of conducting electricity. They are hybrid hydrogels in which conductive materials such as metallic oxides or graphene are incorporated into the hydrogels for the conduction of electricity.

- Uses: Conductive hydrogels have found their use in biosensors, energy storage devices, and tissue engineering.

- Conductive hydrogels are capable of conducting electricity. They are hybrid hydrogels in which conductive materials such as metallic oxides or graphene are incorporated into the hydrogels for the conduction of electricity.

Hydrogel Types Classified by Physical Form:

Lastly, these materials can also be categorized by their physical form, such as sheets and amorphous gels. We discuss each of these below.

- Sheet Hydrogels

- Sheet hydrogels are thin, flat layers often used in applications like hydrogel wound dressings and facial masks. Their uniform thickness makes them ideal for controlled drug delivery and skin treatments.

- Amorphous Hydrogels

- Amorphous hydrogels do not have any defined shape. They are typically used in applications requiring flexibility, such as hydrogel bandages or injectable forms. These gels conform to irregular surfaces, providing excellent coverage.

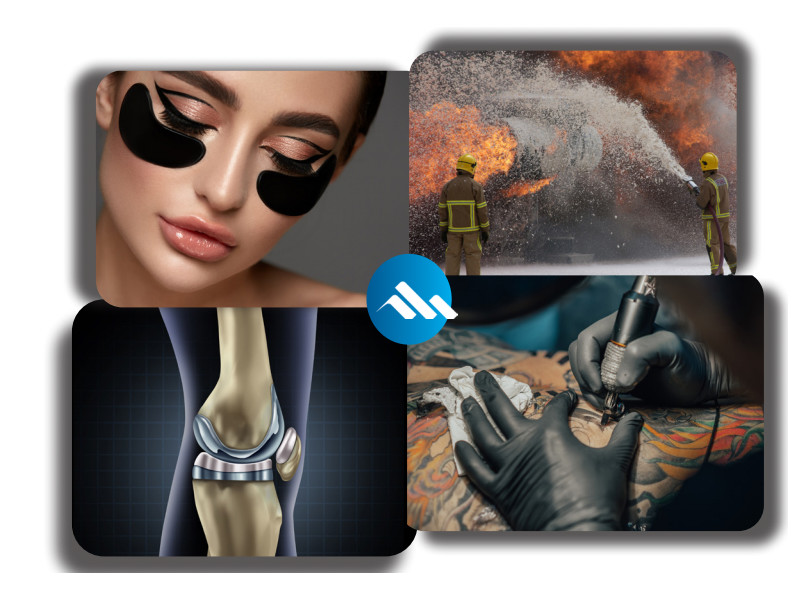

8 Common Uses of Hydrogel

The wide-ranging and tunable properties of hydrogel make them suitable for a very large range of uses. They have found use in mostly every industry, from medical to industrial to consumer products and beyond.

Below, we touch on some of the most common applications for hydrogels by industry.

Medical Uses for Hydrogel

Hydrogels have found various applications in modern medicine.6-8 They offer solutions for wound care, drug delivery, and more.

Some of the many medical applications for hydrogels include (but are not limited to):

- Wound Dressings: Used for wound care, these dressings keep wounds moist, promote healing, and reduce pain.

- Burn Dressings: Provide cooling and hydration, reducing pain and preventing infection.

- Drug Delivery Systems: Hydrogels can encapsulate drugs, allowing controlled and sustained release of the medication.

- Hydrogel Injections: Used in regenerative medicine to deliver cells or therapeutic agents.

- Hydrogel Eye Patches: Enhance hydration and deliver nutrients to sensitive eye areas.

- Ocular implants and contact lenses: Modern silicone hydrogel contact lenses are a revolution in eye care, which offers greater comfort and ocular health benefits than traditional contact lenses.

- Biosensors and diagnostic devices: Conductive hydrogels are used as flexible, sensitive platforms for electrochemical biosensors.

- Tissue engineering: Hydrogels can serve as scaffolds to support cell growth and tissue regeneration. They are particularly useful for cartilage, wound healing, and other applications.

Hydrogel Coatings

Hydrogel coatings9,10 enhance the functionality of various surfaces by providing the following characteristics:

- Lubricity: Reducing friction in medical devices, such as catheters and more.

- Biocompatibility: Enhancing interaction with biological tissues.

- Anti-Biofouling: Preventing microbial growth on surfaces.

Personal Hygiene Products

Hydrogel is commonly used in personal hygiene products.11 Some of the most common hygiene uses include:

- Diapers: Their super absorbent nature is extremely effective in locking in and holding moisture.

- Sanitary Pads: Provide comfort and high absorption.

Cosmetics Products

Hydrogels are widely used in cosmetics12 for applications, such as:

- Hydrogel Face Masks: Deliver hydration and nutrients to the skin.

- Eye Patches: Soothe and rejuvenate tired eyes.

Microfluidics

Hydrogels act as scaffolds for cells in microfluidic devices13, such as in drug tests and diagnostics. This is essential as mimicking biologically relevant tissue is essential for all lab-on-a-chip technologies.

Agriculture and Farming

These materials are also being put to use for agriculture and farming uses,16,17 including:

- Agriculture and horticulture: Hydrogels can be used as soil amendments to improve water retention and nutrient delivery for plants.

- Slow-release fertilizers: These materials can be used to encapsulate and slowly release fertilizers.

Food Industry

Due to their properties and functionality, they are also useful in several food and food packaging applications,16,17 including:

- Food additives and ingredients: Hydrogels made from natural polymers like pectin and chitosan can be used as gelling agents, texturizers, and preservatives in food products.

- Food packaging: Hydrogel-based packaging materials can extend the shelf life of perishable foods like fruits and vegetables.

Other Industrial Applications for Hydrogel

- Soft Robotics: Tough, stimuli-responsive hydrogels can be used to fabricate soft robotic components.18

- Flexible electronics: Conductive hydrogels can be used in flexible, wearable electronic devices.19

- Adhesives and sealants: Supramolecular adhesive hydrogels can be used as fit-to-shape sealants and adhesives.

- Separation and purification: Hydrogels can be used for size-selective separation and purification. This technique is also employed for useful protein purification.20

- Wastewater treatment: Hydrogels can be used to adsorb and remove pollutants like heavy metals from wastewater.21,22

Hydromer™ Hydrogels Offer Customizable Solutions

Hydromer Inc. is a hydrogel manufacturer. Our company develops advanced polymeric hydrogels that are biocompatible, physically stable, and durable. They can be used in a wide range of medical, cosmetic, and industrial applications. All of our hydrogels are custom engineered, which means they can be designed to meet the specific requirements of your application and product needs.

What sets Hydromer apart from other hydrogel manufacturers is our cradle to grave support and services. Hydromer offers its customers expert technical consulting and support services, R&D services, analytical testing, contract manufacturing services and technology transfer services.

For learn more about our advanced hydrogel solutions, visit Hydromer Hydrogels.

Conclusion

Hydrogels are very unique materials. They are used in a wide range of medical, industrial, and food products. From hydrogel wound dressings to face masks and advanced medical applications, these materials are allowing innovation in several areas. Hydromer, Inc. is leading the way in developing advanced hydrogel materials used for cutting-edge technologies. We are also providing customized solutions based on our customers’ needs. As research advances, we can expect even more groundbreaking applications for hydrogels, making them a cornerstone of future technologies.

Contact us today to learn more about Hydromer Hydrogels and how they can be used for your application.

References

1. Peppas NA, Hoffman AS. Hydrogels. Biomaterials science. Elsevier; 2020:153-166.

2. Chirani N, Yahia LH, Gritsch L, Motta FL, Chirani S, Farè S. History and applications of hydrogels. Journal of biomedical sciences. 2015;4(02):1-23.

3. Maitra J, Shukla VK. Cross-linking in hydrogels-a review. Am J Polym Sci. 2014;4(2):25-31.

4. Kaith BS, Singh A, Sharma AK, Sud D. Hydrogels: synthesis, classification, properties and potential applications—a brief review. Journal of Polymers and the Environment. 2021;29(12):3827-3841.

5. Khan F, Atif M, Haseen M, et al. Synthesis, classification and properties of hydrogels: Their applications in drug delivery and agriculture. Journal of Materials Chemistry B. 2022;10(2):170-203.

6. Patel DK, Jung E, Priya S, Won S-Y, Han SS. Recent advances in biopolymer-based hydrogels and their potential biomedical applications. Carbohydrate polymers. 2024;323:121408.

7. Zhou H, Zhu Y, Yang B, et al. Stimuli-responsive peptide hydrogels for biomedical applications. Journal of Materials Chemistry B. 2024;12(7):1748-1774.

8. Hoffman AS. Hydrogels for biomedical applications. Advanced drug delivery reviews. 2012;64:18-23.

9. Liu J, Qu S, Suo Z, Yang W. Functional hydrogel coatings. National Science Review. 2021;8(2):nwaa254.

10. Zhao C, Zhou L, Chiao M, Yang W. Antibacterial hydrogel coating: Strategies in surface chemistry. Advances in colloid and interface science. 2020;285:102280.

11. Bashari A, Rouhani Shirvan A, Shakeri M. Cellulose‐based hydrogels for personal care products. Polymers for Advanced Technologies. 2018;29(12):2853-2867.

12. Parente ME, Ochoa Andrade A, Ares G, Russo F, Jiménez‐Kairuz Á. Bioadhesive hydrogels for cosmetic applications. International journal of cosmetic science. 2015;37(5):511-518.

13. Goy CB, Chaile RE, Madrid RE. Microfluidics and hydrogel: A powerful combination. Reactive and Functional Polymers. 2019;145:104314.

14. Ali K, Asad Z, Agbna GHD, Saud A, Khan A, Zaidi SJ. Progress and Innovations in Hydrogels for Sustainable Agriculture. Agronomy. 2024;14(12):2815.

15. Kaur P, Agrawal R, Pfeffer FM, Williams R, Bohidar HB. Hydrogels in agriculture: Prospects and challenges. Journal of Polymers and the Environment. 2023;31(9):3701-3718.

16. Zhang H, Zhang F, Yuan R. Applications of natural polymer-based hydrogels in the food industry. Hydrogels based on natural polymers. Elsevier; 2020:357-410.

17. Shewan HM, Stokes JR. Review of techniques to manufacture micro-hydrogel particles for the food industry and their applications. Journal of Food Engineering. 2013;119(4):781-792.

18. López-Díaz A, Vázquez AS, Vázquez E. Hydrogels in Soft Robotics: Past, Present, and Future. ACS nano. 2024;18(32):20817-20826.

19. Zhang Y, Tan Y, Lao J, Gao H, Yu J. Hydrogels for flexible electronics. ACS nano. 2023;17(11):9681-9693.

20. Park C-H, Son CK, Park JH, Chung IS. Separation and purification of useful proteins using hydrogel ultrafiltration. Biotechnology and bioprocess engineering. 1997;2:113-116.

21. Akter M, Bhattacharjee M, Dhar AK, et al. Cellulose-based hydrogels for wastewater treatment: A concise review. Gels. 2021;7(1):30.

22. Ahmaruzzaman M, Roy P, Bonilla-Petriciolet A, et al. Polymeric hydrogels-based materials for wastewater treatment. Chemosphere. 2023;331:138743.