The medical device industry has transformed modern healthcare by providing not only lifesaving and life-improving equipment but also an array of devices. Successful medical devices, however depend on performance, durability, and safety. A large part of their effectiveness is driven by the quality of the device’s surface treatment. One of those treatments are hydrophilic coatings, which have presented themselves as a promising technique to improve the performance of medical devices. These coatings reduced friction, improve patient comfort, and enhance operating precision.

This article encompasses what hydrophilic coatings are, why they are used in medical devices, their benefits, and their myriad applications within the medical field. First, we cover some basics, such as what a surface treatment is.

What is surface treatment?

Surface treatment can be defined as the process that modifies the surface of a material. The goal is to enhance properties such as biocompatibility, corrosion resistance, adhesion, lubricity, and sterilization.

Surface treatment is the most critical process in the medical device industry. This is because it helps to significantly increase the efficacy and safety of the medical devices.

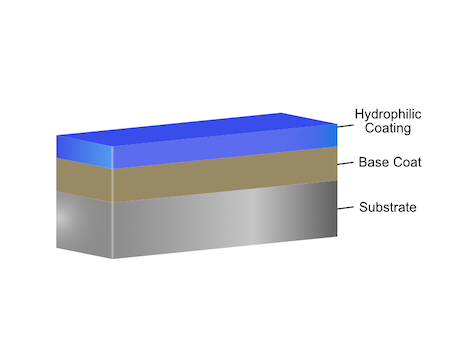

One such surface treatment commonly used is hydrophilic surface modification, by way of applying a hydrophilic coating to the medical device.

What is a Hydrophilic Coating?

Hydrophilic coatings are specialized thin layers applied on medical devices. This, in turn, makes the external part of the device “water-loving” and “slippery-when-wet”. The coatings create hydrophilic layers that almost act like magnets. But instead of attracting metal the coating attracts water molecules from the surroundings’ fluid. After it gets wet, the coating becomes smooth and slippery.

Coating medical devices with hydrophilic coatings helps to increase the wettability of the device dramatically. With the coating the devices are able to attract and hold a great amount of water on their surfaces. Due to this water attraction and slippery layer the medical devices can be easily inserted inside the body tissues. That is because hydrophilic coatings reduce friction and help to lower the chances of fouling and thrombosis, common complications with the use of medical appliances like catheters, stents, and prostheses.1-3

Common Polymer Coating Options for Medical Device Coatings

Medical devices are coated with Hydrophilic polymers, such as:

- Poly(acrylicacid), Polymethacrylate and Other AcrylicPolymers

- Poly(ethyleneglycol) and Poly(ethyleneoxide)

- Poly (vinyl alcohol) (PVA) and Copolymers

- Polyvinyl pyrrolidone (PVP)

- Polyethylene glycol (PEG). When these polymers are moistened, they form a slippery surface that must be overcome by a high friction force between the device and body tissues. Such conditions are a requirement for precise, minimally invasive procedures.

Why Are Hydrophilic Coatings Used for Medical Devices?

The purpose of hydrophilic coating is to create a smooth surface with no friction.

Why?

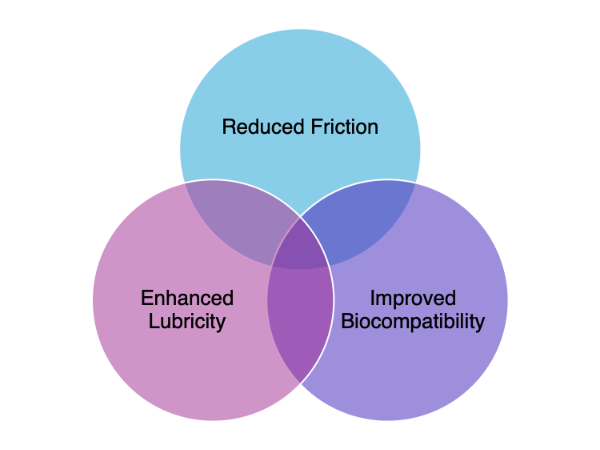

This allows interaction between the device and biological tissue without producing friction. It is particularly crucial that the devices inserted into the human body avoid severe damage to tissue. This make the procedure painless.2,4 For example, hydrophilic coatings made from polymers like polyvinylpyrrolidone (PVP) and polyacrylic acid can significantly reduce friction.

When in contact with the bodily fluids, the hydrophilic coating’s water-attracting properties will provide lubricity, allowing devices to move smoothly. This is vital in various medical applications, such as catheters and guidewires.5

In addition to reducing friction, these coatings can also improve biocompatibility. Specifically, hydrophilic coatings help make the medical device surface biocompatible. Since hydrophilic coatings can mimic the body’s natural moisture-laden environment, they improve the biocompatibility of medical devices by reducing irritation or adverse tissue reactions.

Hydrophilic coatings also help in preventing protein from sticking to the device and can help reduce inflammation. Both of these are important for the long-term success of implanted devices.6,7

The Benefits of Hydrophilic Coatings: Enhanced Performance, Superior Comfort

The benefits of hydrophilic coatings for medical devices extend past reducing friction. These coatings also inhibit microbial adhesion and biofilm formation, which are primary causes of medical device-related infections. For example, hydrophilic coating composed of phosphorylcholine polymers have been shown to have excellent performance in terms of anti-fouling properties. Hydrophilic coating can be applied to different kinds of medical devices such as stents and catheters.8 They can be applied to multiple substrates, including medical devices with more than one substrate. Moreover, hydrophilic coatings are engineered to be antimicrobial, which can further improve their protective capabilities against infections.9

The unique properties of hydrophilic coatings make them invaluable for medical device performance.

Key benefits for medical devices

- Patient Comfort: These coatings reduce friction, which enhances patient comfort during invasive procedures, leading to less pain and a lower risk of complications.

- Precision and Control: The lubricating effect gives medical practitioners superior control during the insertion and passage of the medical device, enhancing procedural accuracy and reducing the risk of accidental tissue damage.

- Efficiency Boost: These coatings lead to lower manipulation forces, which enhance procedural efficiency, reducing intervention times and associated costs

- Extended Device Lifespan: Hydrophilic coatings tend to increase the life of devices. This is because hydrophilic coating decreases friction-related wear and tear.

- Infection Control: Hydrophilic coatings can have antimicrobial properties, adding another level of security against infection because implantable devices stay in a body for such a long period.

Common Uses and Applications of Hydrophilic Coatings in Medical Devices

Hydrophilic coatings are widely used in a number of applications when it comes to medical devices.

For example, they are used in catheters, guidewires, and inflatable penile prostheses, where their ability to be lubricious is an essential requirement for the device’s functionality and comfort to the patient.2,10

The coatings have the potential to fit into a high number of medical applications, such as examples in cardiovascular devices and orthopedic implants, hence increasing the final performance in the patients.3,4

Hydrophilic coatings have broad applications across a range of medical devices where friction reduction, precision, patient comfort and other key attributes are critical. Common medical device applications include:

- Catheters: Used in cardiovascular, urological, and gastrointestinal procedures, catheters benefit from hydrophilic coatings due to their ability to reduce friction, ease insertion, and minimize the risk of trauma.

- Guidewires: For navigating through blood vessels or other narrow pathways, guidewires require high levels of control and flexibility. Hydrophilic coatings make them more effective.

- Endoscopes and Scopes: Coatings on endoscopes reduce discomfort during insertion and provide clearer imaging by reducing tissue buildup on the device.

- Needles and Syringes (needle coatings): Hydrophilic coatings on needles facilitate smoother entry and reduce resistance, enhancing both patient comfort and procedural accuracy.

- Implantable Devices: Certain implantable devices, such as stents, benefit from hydrophilic coatings that improve biocompatibility and can potentially reduce the risk of infection.

Hydromer™ Hydrophilic Medical Coatings

Hydromer™ hydrophilic coatings are formulated for cardiovascular, circulatory, neurovascular, urological, and vascular devices. Hydromer hydrophilic medical device coatings offer not only lubricity, but other functionalities such as low particulate, enhanced adhesion, thrombo resistance, and durability. Please refer to the tables below to check devices, substrates, functionalities of our products. Most of our formulations have MAF files.

Our Line of Medical Device Coatings

Our company formulates custom hydrophilic coatings for all medical device coating applications, including:

- Thromboresistant Coatings – our thromboresistant coatings are “slippery-when-wet” and are non-leaching, which can reduce blood clotting when coming in contact with medical devices. As a result, Hydromer™ thromboresistant coatings dramatically improve patient safety and clinic outcomes.

- One-Step Coatings – our one-step hydrophilic surface modification makes coating substrates less complex and more cost-effective by reducing the need for multiple-step coatings.

- Cell-Growth Enhancing Coatings – these coatings are more biocompatible and encourage cellular attachment. As a result, they have been shown to enhance adhesion and proliferation of fibroblast and endothelial cells and increase wound healing and cell repair.

- Primers – our preparing substrates to accommodate coating applications for better adhesion. They work with a wide range of substrates.

Learn more about Hydromer Medical Device Coatings.

Conclusion

Hydrophilic coating are important for improving the use, effectiveness, and safety of medical devices. These coatings offer a biocompatible surface that helps tackle the problems related to device-tissue interactions. Use of these coatings ultimately leads to smoother procedures and improved patient compliance. In conclusion, hydrophilic coating technologies have become a significant advance in medical device technology. This surface modification helps with reduction in friction, inhibition of bacterial adhesion, and improvement in biocompatibility, among other things. All of this makes them indispensable for modern medical device coatings applications.

References:

- Hydrophilic catheters: an evidence-based analysis. Ontario health technology assessment series. 2006;6(9):1-31.

- Ajdnik U, Luxbacher T, Vesel A, et al. Polysaccharide-Based Bilayer Coatings for Biofilm-Inhibiting Surfaces of Medical Devices. Materials (Basel, Switzerland). Aug 21 2021;14(16)doi:10.3390/ma14164720

- Jia Y, Yang Y, Zhang H. Comparative Study on the Lubrication Mechanism and Performance of Two Representative Ionic and Nonionic Self-Adhesive Polymer Coatings. Langmuir. 2024/04/16 2024;40(15):8271-8283. doi:10.1021/acs.langmuir.4c00539

- Albers PTM, Govers SPW, Laven J, et al. Design of dual hydrophobic-hydrophilic polymer networks for highly lubricious polyether-urethane coatings. European Polymer Journal. February 01, 2019 2019;111:82-94. doi:10.1016/j.eurpolymj.2018.12.004

- Butruk-Raszeja B, Trzaskowski M, Ciach T. Polyvinylpyrrolidone-Based Coatings for Polyurethanes – The Effect of Reagent Concentration on Their Chosen Physical Properties. Inzynieria Chemiczna i Procesowa. 12/01 2012;33:563-571. doi:10.2478/v10176-012-0046-6

- Chan D, Maikawa CL, d’Aquino AI, Raghavan SS, Troxell ML, Appel EA. Polyacrylamide-based hydrogel coatings improve biocompatibility of implanted pump devices. Journal of biomedical materials research Part A. Jul 2023;111(7):910-920. doi:10.1002/jbm.a.37521

- Zhou G, Loppnow H, Groth T. A macrophage/fibroblast co-culture system using a cell migration chamber to study inflammatory effects of biomaterials. Acta biomaterialia. Oct 2015;26:54-63. doi:10.1016/j.actbio.2015.08.020

- Kaneko T, Saito T, Shobuike T, et al. 2-Methacryloyloxyethyl Phosphorylcholine Polymer Coating Inhibits Bacterial Adhesion and Biofilm Formation on a Suture: An In Vitro and In Vivo Study. BioMed research international. 2020;2020:5639651. doi:10.1155/2020/5639651

- Desrousseaux C, Sautou V, Descamps S, Traoré O. Modification of the surfaces of medical devices to prevent microbial adhesion and biofilm formation. Journal of hospital Infection. 2013;85(2):87-93.

- Kaewpirom S, Piboonnithikasem S, Sroisroemsap P, Uttoom S, Boonsang S. Tailoring silk fibroin hydrophilicity and physicochemical properties using sugar alcohols for medical device coatings. Scientific Reports. 2024/06/14 2024;14(1):13781. doi:10.1038/s41598-024-64450-5